- April 24,2017.

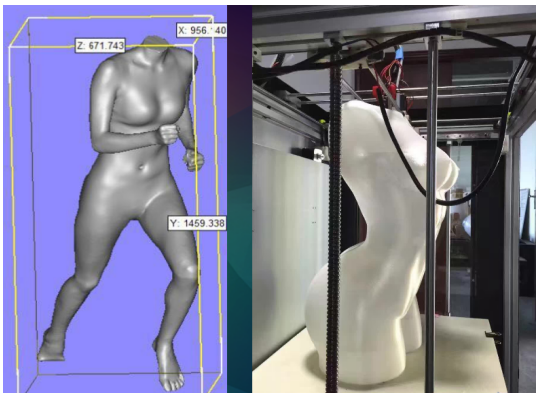

With the continuous development of 3D printing technology, the traditional model of the production industry is also experiencing an industrial technological innovation. All along, the model industry are based on manual development, manual production, product development has been a problem. No prototype of the product, first of all need artificial clay sculpture prototype, clay sculpture out of the prototype may not be able to shape, need to repeatedly modify to meet the requirements of this clay is very time-consuming process, clay cost is very expensive, each modification takes a lot of cost the cost of. And this product out of the rigid plastic movement, the shape is not realistic, the overall proportion of the body is often easy to imbalance. Clay sculpture out of the product is only a prototype, the mold sample sector also need to Taiwan as the basis for the prototype to turn the mold, and other real models turned out to make the sample before we know whether the form of pre-compliance with customer standards, the size is reasonable. The whole process is expected to take about 20 days, plus the cost of plastic mold cost about US $ 1520 or so.

In short, the gradual promotion of 3D technology is a positive impact on the traditional handicraft industry, I believe in the near future, 3D technology will be widely used in the model manufacturing industry.

Cheap Fashion Style Male Mannequin For Sale

Full Body Fiberglass Standing Mannequins Female Wholesale

Fashion Full Body Cheap Female Mannequins For Sale

Cheaper Muscle Male Mannequin For Sale

Lifelike Baby Mannequin For Display

Wholesale Black Fashion Male Mannequin

Cheap Headless Male Mannequin For Sale

Sexy Female Leg Mannequin For Pants Display

Cheap Used Child Display Mannequins For Sale

Fiberglass Matte Black Male Mannequin

Fashion Window Display Female Sexy Dressmaking Sitting Manikin

2017 Sport Male Egg Head Runner Sporty Athletic Mannequin Running Pose for Male Clothing Store Display Model Mannequins